<tc>Flow-forming</tc>

FlowForming

Less weight per wheel without sacrificing stability - the FlowForming technology makes it possible. In this process, parts of the cast rim blank are rolled out and compacted. This not only saves raw materials, but also enables reduced wall thicknesses with extreme stability - a decisive advantage in terms of driving dynamics in the area of unsprung mass. The lower weight per vehicle also reduces CO2 emissions. Real benefits for drivers and the environment.

-

1. Aluminum bars 6061/7075

-

2. Cutting

-

3. Forging T6 heat treatment

-

4. Forged rolls

-

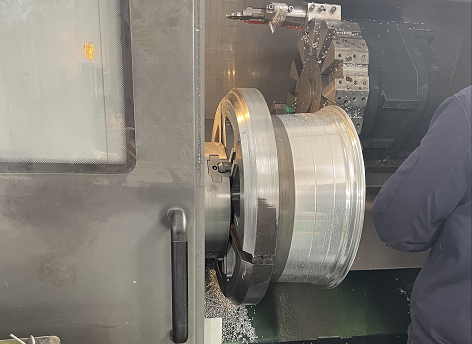

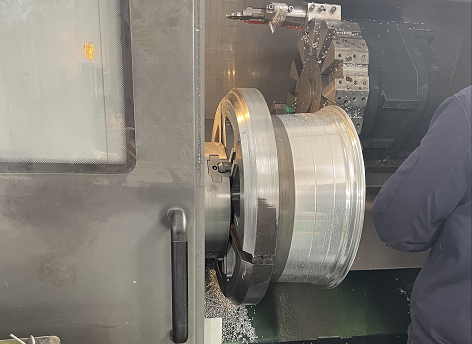

5. Pre-rotation

-

6. Pre-turned blanks

-

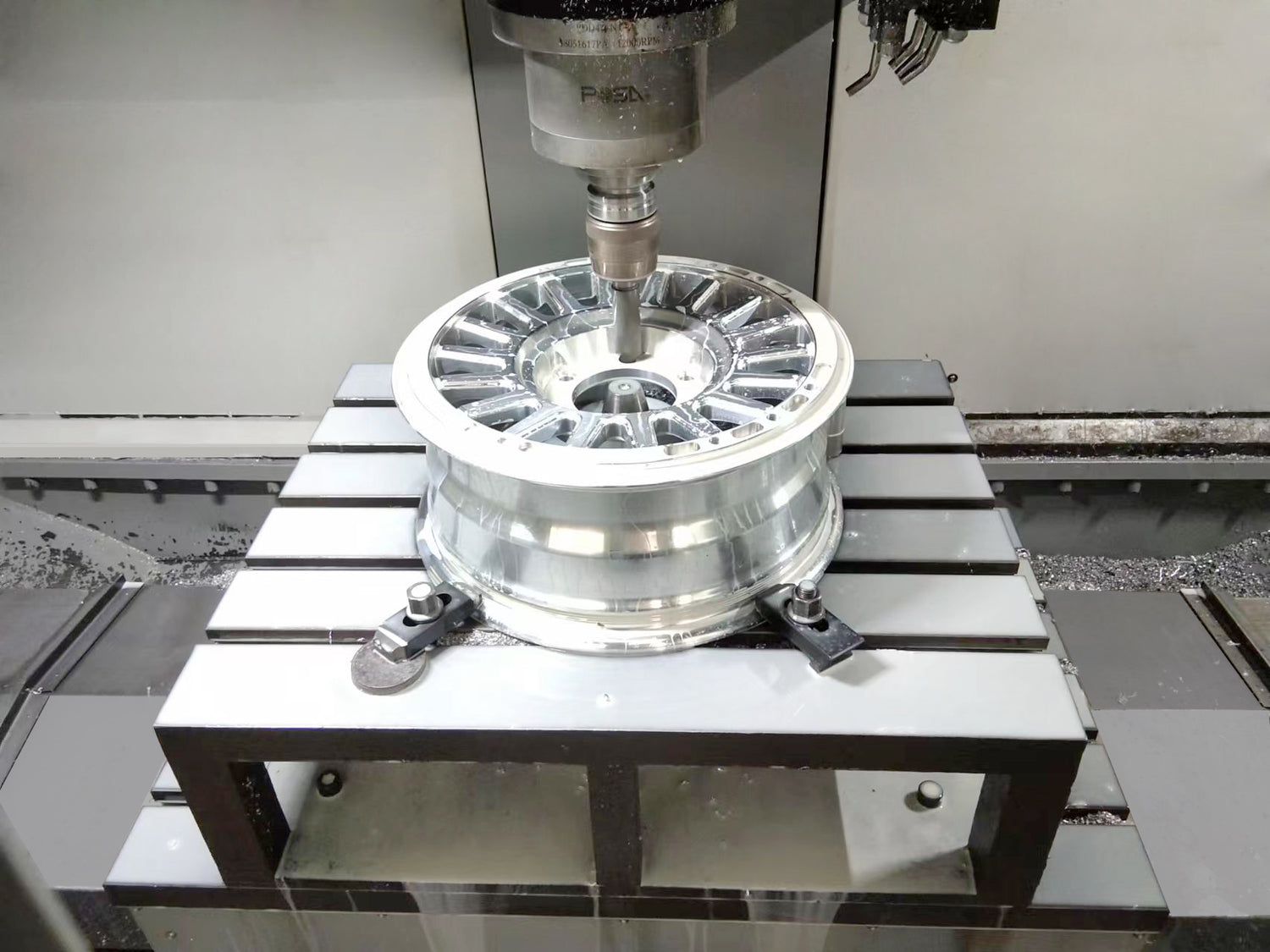

7. CNC milling

-

8. Paintwork

-

9. Internal strength tests

<tc>CNC machining</tc>

CNC machining is a very important process for forged wheels. With our CNC control system and specially developed CAD/CAM software, we are able to turn your idea of the perfect car into reality. Thanks to our special designed clamping devices and oil-damped tool holders, we are able to manufacture the wheels with particularly low vibrations and the highest precision.

<tc>The powder coating</tc>

For our forged rims, we always coat it with high level German original Acrylic Powder Clearcoats.

The acrylic coating is characterized by easy to clean, excellent anti-corrosion performance, abrasion resistance and impact resistance.

<tc>New production base</tc>

Since the beginning of 2020, we have the new production base in Ganzhou China. with quality orientation and advanced technologies, we manufacture exclusive forged wheels for our customers. Even against the background of of the new coronavirus, nothing has happened here so far, and we has been carrying out production orderly!