<tc>Forging</tc>

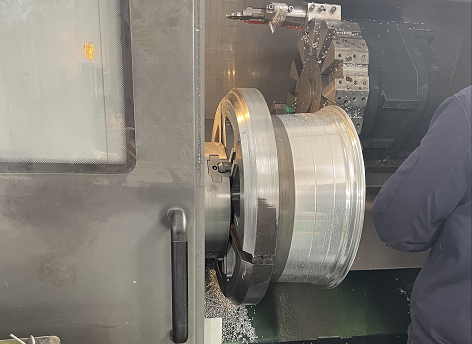

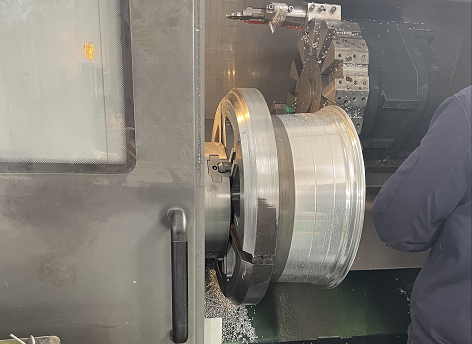

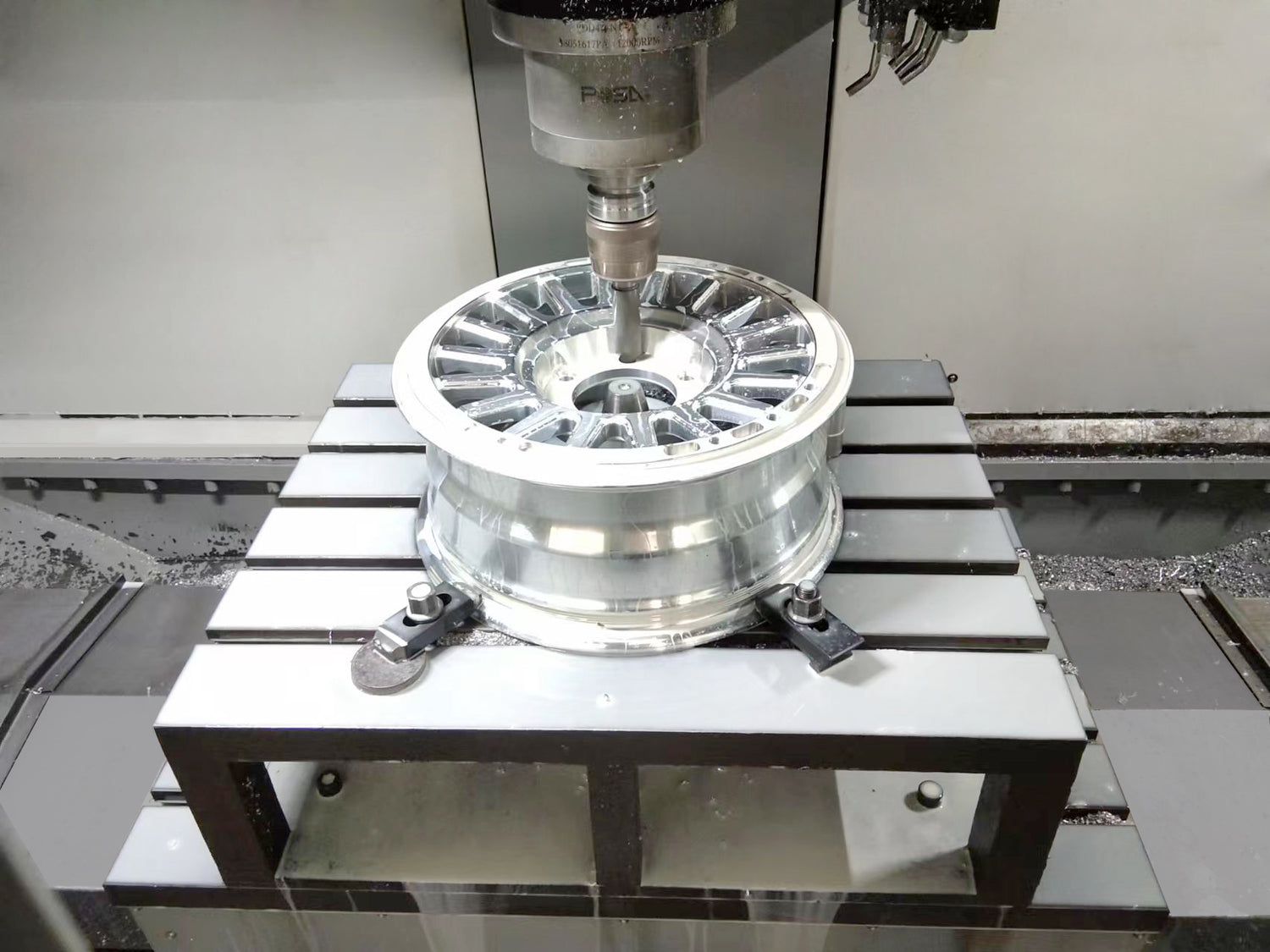

In the forging process, the aluminum alloy bar (6061/7075) is first forged into a forging billet through a multi-stage forging process. The raw material is processed and shaped several times in a forging press with a force of about 10,000 tons. At the same time, it must be heated repeatedly (T6 heat treatment). In the first stage, the rod is compressed into a disc. In stage 2, the disc is pressed into the shape of a narrow forged billet of specific dimensions. The rims are designed with suitable blank drawings, then turned and milled on CNC machines.

Forging technology can produce wheels of exceptional strength. The complex forging technique results in a higher material density of the light metal alloy, which ensures higher strength compared to conventional casting techniques. Potential pores and cavities are eliminated. Material thickness can also be chosen to be lower than casting and flow forming wheels. Due to the thickness of the material, the correspondingly finely machined forged alloy wheels are noticeably lighter and more refined. The resulting reduction in unsprung mass contributes significantly to improved driving dynamics.

-

1. Aluminum bars 6061/7075

-

2. Cutting

-

3. Forging T6 heat treatment

-

4. Forged rolls

-

5. Pre-rotation

-

6. Pre-turned blanks

-

7. CNC milling

-

8. Paintwork

-

9. Internal strength tests

<tc>CNC machining</tc>

CNC machining is a very important process for forged wheels. With our CNC control system and specially developed CAD/CAM software, we are able to turn your idea of the perfect car into reality. Thanks to our special designed clamping devices and oil-damped tool holders, we are able to manufacture the wheels with particularly low vibrations and the highest precision.

<tc>The powder coating</tc>

For our forged rims, we always coat it with high level German original Acrylic Powder Clearcoats.

The acrylic coating is characterized by easy to clean, excellent anti-corrosion performance, abrasion resistance and impact resistance.

<tc>New production base</tc>

Since the beginning of 2020, we have the new production base in Ganzhou China. with quality orientation and advanced technologies, we manufacture exclusive forged wheels for our customers. Even against the background of of the new coronavirus, nothing has happened here so far, and we has been carrying out production orderly!